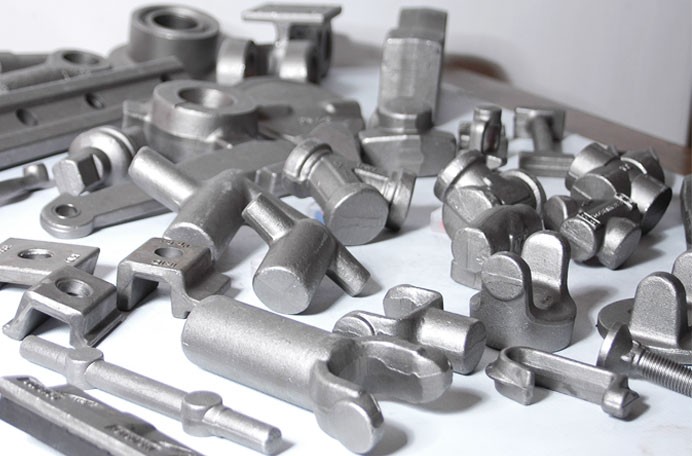

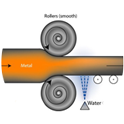

Forging (Forging) work on metal mallet or pressing work and bringing it into a useful form. Forging is the oldest working art and its origin goes back to very ancient times. This process is used in large forces and work equipment are often very heavy.